The printing industry features a diverse array of presses and applications. That’s why the best flexo doctor blade systems adapt to fit your needs. Using a customizable system that’s designed to work with your equipment gives you more operational flexibility and optimizes your press’s performance across multiple jobs.

The printing industry features a diverse array of presses and applications. That’s why the best flexo doctor blade systems adapt to fit your needs. Using a customizable system that’s designed to work with your equipment gives you more operational flexibility and optimizes your press’s performance across multiple jobs.

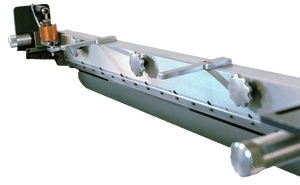

How do they work? First, the designer examines a computer model of your press configuration to determine optimal wiping angles. Then, the blade system is calibrated to produce the best results based on that model. This effectively eliminated problems commonly found in blade holders.

It also allows you to improve consistency. When you can quickly and easily recreate the perfect blade setting every time you run a job, you effectively distribute ink every time it’s needed. That level of reliability lets you ensure quality control for every customer – all with a single upgrade to your press.

On the other hand, it also allows the same press to meet flexible job requirements by retaining the fountain roll. Custom-made systems are the best way to blend consistency and adaptability, two factors that define your ability to meet industry needs and your reputation as a trusted leader in quality printing that your customers can count on.