Doctor blades made from steel are known to produce excellent results on high line screen anilox rolls and other difficult metering applications. However, as with all doctor blade materials, steel doctor blades do have some disadvantages. When incorrectly applied, they can produce metal fragments which could lead to anilox scoring. Additionally, operators also have a risk of cut hazards when handling used steel doctor blades if the proper PPE and procedures are not utilized.

Doctor blades made from steel are known to produce excellent results on high line screen anilox rolls and other difficult metering applications. However, as with all doctor blade materials, steel doctor blades do have some disadvantages. When incorrectly applied, they can produce metal fragments which could lead to anilox scoring. Additionally, operators also have a risk of cut hazards when handling used steel doctor blades if the proper PPE and procedures are not utilized.

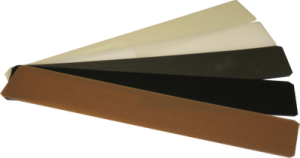

Plastic blades can offer a better option than typical carbon steel doctor blades when used with certain applications. Plastic blades work best when metering water based inks on lower line screen anilox rolls typically less than 500 LPI. Plastic blades will provide longer life when compared to carbon steel blades, will not corrode with water based inks, will not release fragments that can cause anilox scoring, and will reduce the potential for cut hazards. Please be aware that worn Plastic blades will present a cut hazard and proper PPE and procedures will still need to be followed when handling them. They are a popular option for corrugated applications and containment blades on chambered inking systems.

There are many choices when it come to materials and edge shapes. Contact us so we can discuss your application to determine if Plastic blades are a good option for your jobs.