Gravure printing was developed hundreds of years ago and is still a viable method of printing today. Well known for its excellent print quality and consistency over long runs, it can be the printing method of choice for demanding print jobs. Also known as rotogravure, it is a relief method of printing where the image to be printed is engraved below the surface of a chrome-plated cylinder. The durability of the chrome-plated cylinder and the direct image transfer from the cylinder to the substrate are two of the reasons for the high quality and consistency of the process. However, the process of engraving the cylinder can lead to high costs, particularly for short-run jobs, when compared to other methods of printing.

Gravure printing was developed hundreds of years ago and is still a viable method of printing today. Well known for its excellent print quality and consistency over long runs, it can be the printing method of choice for demanding print jobs. Also known as rotogravure, it is a relief method of printing where the image to be printed is engraved below the surface of a chrome-plated cylinder. The durability of the chrome-plated cylinder and the direct image transfer from the cylinder to the substrate are two of the reasons for the high quality and consistency of the process. However, the process of engraving the cylinder can lead to high costs, particularly for short-run jobs, when compared to other methods of printing.

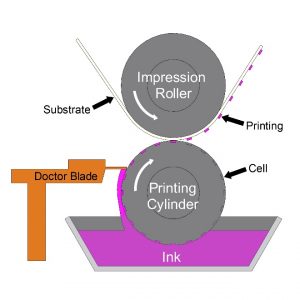

The gravure process is relatively simple in theory. The engraved cells are filled with ink while the cylinder is rotating and partially immersed in a pan of ink. A doctor blade is applied to the surface of the cylinder in a manner that removes all the surface ink from the cylinder without damaging the cylinder. The ink remaining in the cells is then transferred to the substrate as the substrate becomes sandwiched between the cylinder and impression roller. The substrate with the wet layer of ink then goes thru dryers so that the ink is completely dry before the substrate moves to the next station where another ink color is applied.